Phase Separation in Ethanol Gasoline: The Hidden Killer in your Gas Station

Mar 3rd 2019

The use of ethanol as a fuel in the United States has significantly increased over the past decade. Today, greater than 80% of all retail gas stations in the US blend gasoline with up to 10% ethanol (E10).

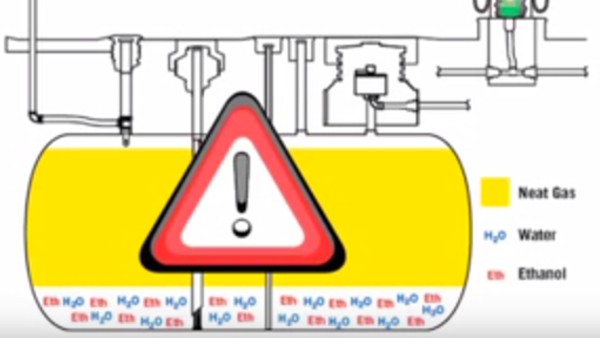

One of the main concerns in the supply and storage of ethanol is the potential for what is called “phase separation” in gasoline that contains ethanol. Phase separation occurs when enough water contaminates the gasoline. This causes the ethanol to attach itself to the water molecules, leaving two distinct layers in the storage tank: a gasoline-only layer at the top and an ethanol/water “cocktail” along the bottom.

There are 3 negative effects of phase separation:

- damage to your retail dispensing infrastructure. The fluid resulting from Phase separation is highly corrosive and can damage your storage tank, submersible pumps, piping and fuel dispensers

- damage to customer vehicles and your gas station brand. Phase separation in most vehicles will cause engines to stall almost immediately, leaving disabled vehicles at the gas station. This will cause a bad image problem and drop in customer loyalty which is hard to recover from

- out of spec or unsaleable fuel. The octane of pure ethanol is approximately 113, so to obtain 87-octane E10 gasoline, the pure gasoline used in this blend is below 87 octane. Thus after phase separation, the pure gasoline left is depleted from the ethanol and is thus of lower octane.

With this in mind, it is imperative that motor fuels containing ethanol not be exposed to water during its distribution or use, making housekeeping at the service station very important in the prevention of water contamination. In an ideal operation, a Gas Station would never get Phase Separation. However it is imperative that you as owner have one or more of the following methods in place in order to detect phase separation as early as it happens.

Detection Methods

Each of the following methods can be implemented alone or in any combination. Each has its own limitations, so the more you use the more protection you will have.

Automatic Tank gauge/ Monitor with water detection

Most modern underground storage tanks have this as integral part of its monitoring. It consist of a 2-way probe: it has 1 floating sensor reporting the lever of fuel and one more reporting the level of water at the bottom. This probe is wired to your console inside your gas station's back office. The following picture shows a typical UST equipped with this system.

The main drawback of this method is that due to the difference in density between water and the fluid resulting from phase separation, the float at the bottom of the probe will indicate the level of water but not necessarily the level of the phase separation fluid which sits on top. This happens because the lower float is calibrated to respond to water's density so it floats in water, but the density of the phase separation fluid is lower than water's and variable. In effect, you can see accumulation of water in the tank but you are blind to phase separation fluid.

Water-Finding Paste

This is a cost-effective, simple process although labor intensive and highly dependent on regularity. "Sticking" the tank, as it is commonly known, is done by applying a special water-finding paste (like our Gasoila All-purpose Water Finding Paste) to the end of a stick and then dip the stick into the tank until it touches the bottom. The paste will change its color to indicate either the presence of water and/or phase separation.

Despite requiring some training and experience to interpret the changes in color of the paste, it can be your most cost-effective activity paired with your Tank Gauge/Water Monitor mentioned earlier. You can establish a baseline of water in your UST, say a very low level and record it with your console hourly and set alarms for subtle changes in level of water. At which point you can quickly inspect if phase separation is present by sticking the tank.

Dispenser Filters

This is not as much a detection method as it is a last line of defense against damaged customer's cars. As you may know, each of your dispensers have a disposable filter that must be replaced regularly (CIM-TEK has the 400MB-30 and 400MB-10, you can see the full 400 Series Spin-on Fuel Dispenser Filters from CIM-TEK here ). Some of these filters will also filter out water, by quickly constricting once water is detected. The result is a very slow flow of fuel out of the nozzle. Therefore, slow flow is a potential indication of water reaching the dispenser.

You should not depend entirely on filters to address phase separation detection. While they may reduce the damage, they do not completely eliminate the potential to get phase separation in a vehicle. Also, be aware that By the time phase separation is detected by a dispenser filter, it has already accumulated in significant volume, leading to much larger remediation costs. In order for phase separation to enter the dispenser, it must have gone through the tanks pumping system and piping. That also means that the tank must contain 5-6 inches of phase separation.

Conclusion

The prevalence of ethanol-blended fuels is increasing the incidence rate and awareness of the phenomena of phase separation. Proposed increases in the ethanol blend levels will further elevate a stations’ risk to phase separation. These risks include damage to the petroleum infrastructure, damage to customer vehicles and station brand equity, and the potential to be left with unsaleable fuel. Your best alternative is to find it as early as possible by using several layers of detection working together.

Not mentioned here are early-detection methods, developed just recently by UST vendors like Veeder-Root which can be considered if planning an upgrade of your UST system.

As always, we are here to serve you and make the operation and maintenance of your gas station equipment predictable, cost-effective and profitable. Call or email us if you have any questions and feel free to leave us your comments as well!!

Have you detected Phase Separation in your storage tanks?... Read our next blog post "So you have Phase Separation in your E10 storage tank..." to see what can be done to reverse the process! Your gas and infrastructure can still be saved!